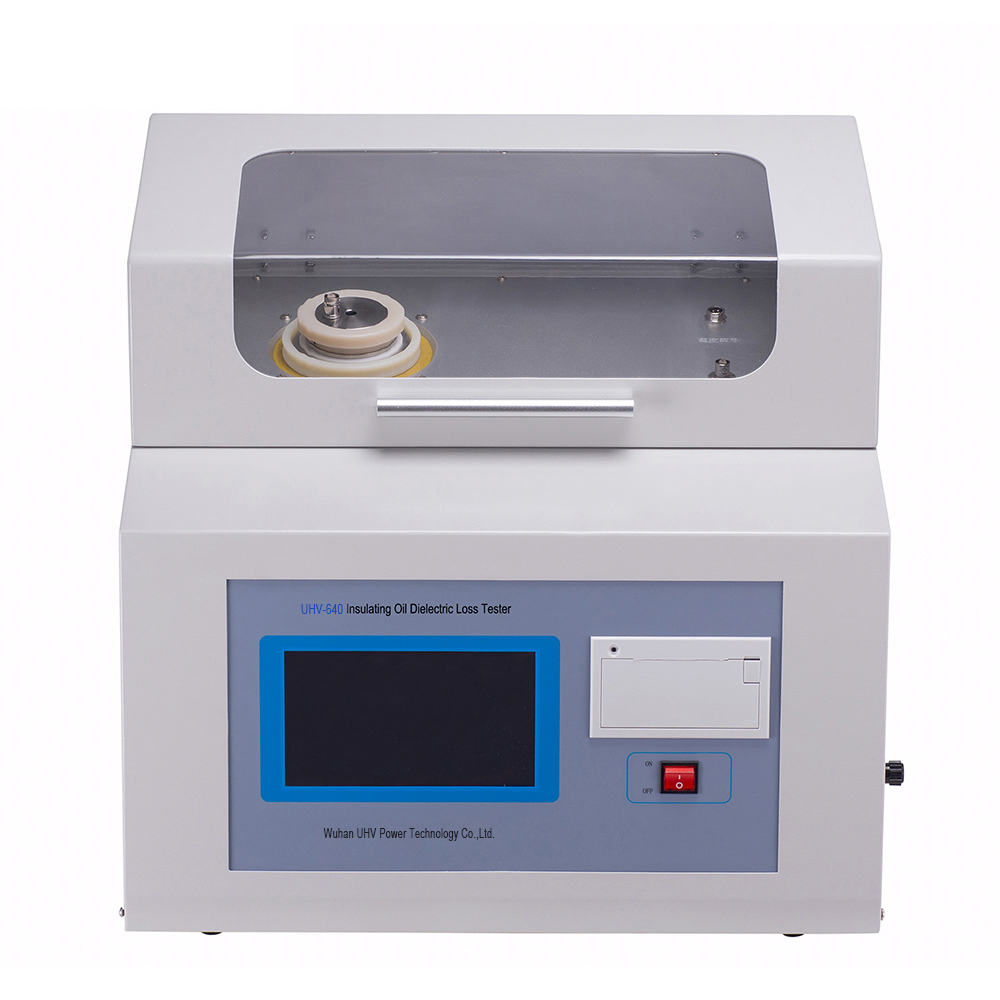

The insulation oil dielectric loss tester under UHV power can help many power workers conduct various power tests more conveniently.

1、 Noun Explanation:

capacitance

Also known as "capacitance", it refers to the amount of charge stored at a given potential difference, denoted as C, and the international unit is Farad (F). Generally speaking, charges move under force in an electric field. When there is a medium between conductors, it hinders the movement of charges and causes them to accumulate on the conductors, resulting in the accumulation and storage of charges. The amount of stored charge is called capacitance.

(Relative) permittivity

The relative permittivity of an insulating material is the ratio of the capacitance C around and between the two electrodes of a capacitor filled with the insulating material to the capacitance q of the same electrode structure in vacuum.

Replacing q with the capacitance of the electrode in air has sufficient accuracy for measuring relative permittivity.

Dielectric loss factor

The dielectric loss factor of insulating materials is the tangent of the loss angle. When the dielectric of a capacitor is composed of only one insulating material, the loss angle refers to the radians of the phase difference between the applied voltage and the resulting current that deviates by π/2.

DC resistivity (volume)

The volume resistivity of insulating materials is the ratio of the DC electric field strength within the material to the steady-state current density.

2、 Measurement purpose

Capacitance rate, dielectric loss factor, and resistivity, whether single or all, are important indicators of the inherent quality and pollution level of insulating liquids. These parameters can be used to explain their potential impact on equipment using the liquid.

3、 Measurement precautions

Measurement sequence:

Applying a direct current voltage to the sample will alter its subsequent measurement of the power frequency. When measuring capacitance, loss factor, and resistivity successively on the same sample, the measurement under power frequency should be carried out before applying DC voltage to the sample. After the power frequency test, the two electrodes should be short circuited for 1 minute before starting to measure the resistivity.

Measurement error factors:

Although severe pollution will affect the capacitance rate. However, trace pollution can strongly affect dielectric loss and resistivity. Unreliable results are usually caused by improper sampling or handling of the sample, contamination from uncleaned test pits, or absorption of water, especially the presence of insoluble water. Long term exposure to strong light during storage can lead to dielectric degradation. Adopting standardized procedures for the storage and transportation of recommended liquid samples, as well as the structure and purification of the test cell, can minimize errors caused by contamination.