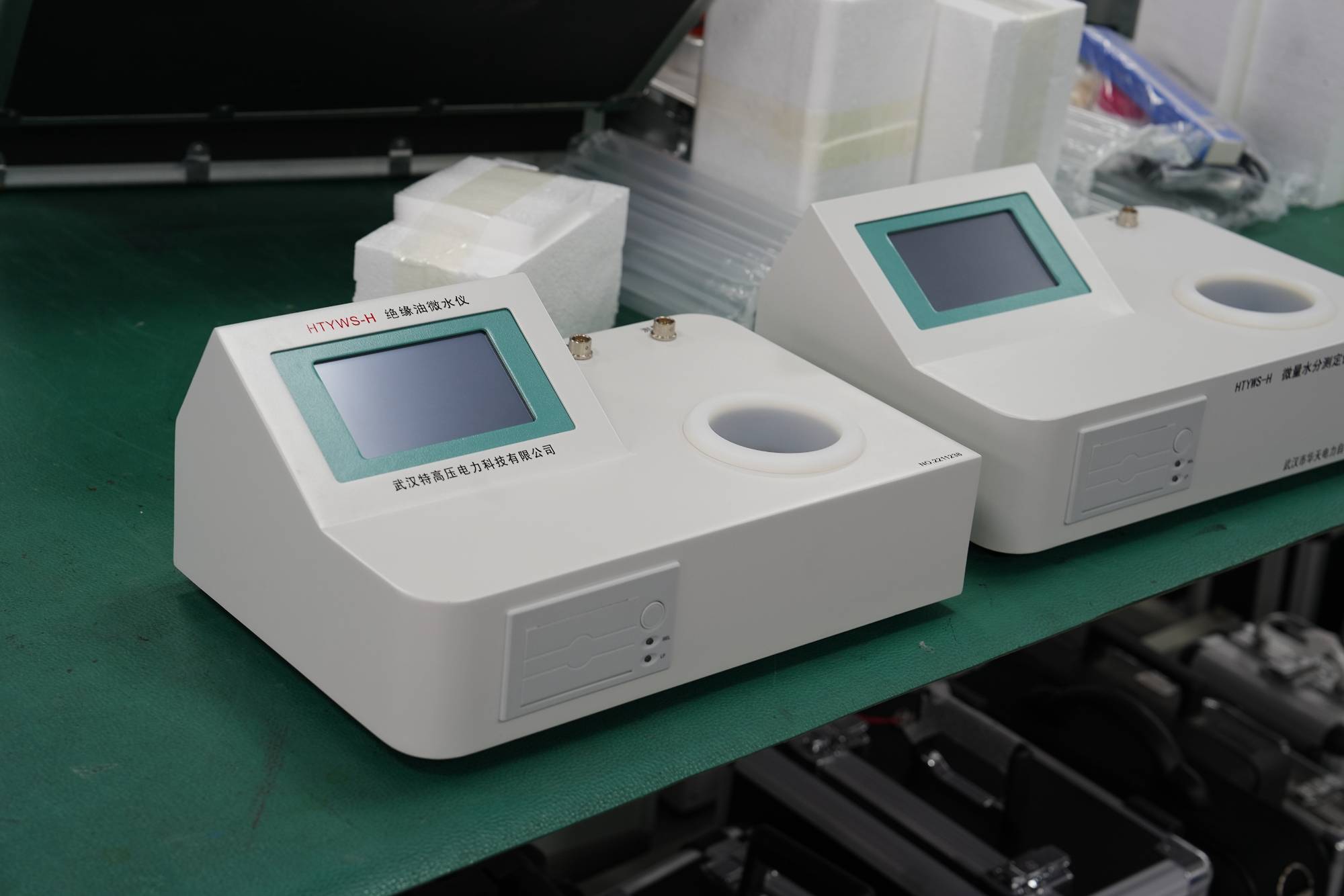

The trace moisture analyzer under UHV power can help many power workers conduct various power tests more conveniently.

measuring principle

In Karl Fischer moisture content measurement, water reacts with iodine and sulfur dioxide in the presence of alkali and alcohol.

[H. sub. 2] O+S [O.sub. 2]+C [H. sub. 3] OH+3 RN+[I.sub. 2] [Right arrow] [RHN] S [O.sub. 4] C [H. sub. 3]+2 [RNH] I (1)

In volumetric titration, iodine is added as a titrant.

In the Coulomb method, iodine is electrolyzed in an anode solution containing iodine ions.

2I - [Right Arrow] [I.sub.2]+2e - (2)

As long as there is water in the titration cell, the generated iodine will react according to reaction (1). Once all the water reacts, excess iodine will appear in the anolyte. Iodine was detected by a platinum electrode, and the production of iodine stopped. According to Faraday's law, the amount of iodine produced is proportional to the current produced. In equation (1), [I.sub. 2] and [H. sub. 2] O react with each other in a 1:1 ratio.

Therefore, one mole of water (18 g) is equivalent to 2 x 96500 coulombs (or 10.72 coulombs/1 mg [H. sub.2] O). Therefore, the total amount of moisture can be determined by measuring the total power consumption.

Experiments used

chemical

Natural rubber (NR), styrene butadiene rubber (SBR), polyvinyl alcohol (PVA), ethylene propylene rubber (EPDM), and nylon 6 are all sourced from standard commercial sources. The Karl Fischer reagent used for moisture determination is from Merck. The water standard (0.1%) traceable to NIST's SRM 2890 comes from Merck.

analysis

Before starting the analysis, the temperature and flow rate are controlled by a digital controller. Dry nitrogen is passed through the heating chamber and reaction tank to eliminate internal moisture. Next, perform pre titration to eliminate the moisture in the anolyte. Calculate the moisture content according to Equation 3 below:

Moisture (ppm)=(Data Drift * T - Blank)/W * F (3)

Among them: data - measured moisture content (micrograms); T=measurement (titration) time (seconds); W=sample weight (g); F=Factor; Blank=Blank value (micrograms); Drift=Drift before measurement (micrograms/second).

Determine the factor by measuring the concentration of the standard aqueous solution directly injected into the anode solution. Divide the measured value by the reported value (from the certificate) to calculate the coefficient.

Determine the blank by running the carrier gas (at the same time as the sample measurement) and measuring the moisture content.

When the instrument stabilizes after any other pre titration measurement, the instrument will automatically calculate the drift value.

During the measurement process, the polymer is cut into small pieces and placed in a sample boat. Take about 2-3 g of sample for analysis.

The sample temperature is maintained at 125 ℃ and the heating time is 30 minutes. High heating temperatures should be avoided to reduce the possibility of sample decomposition.