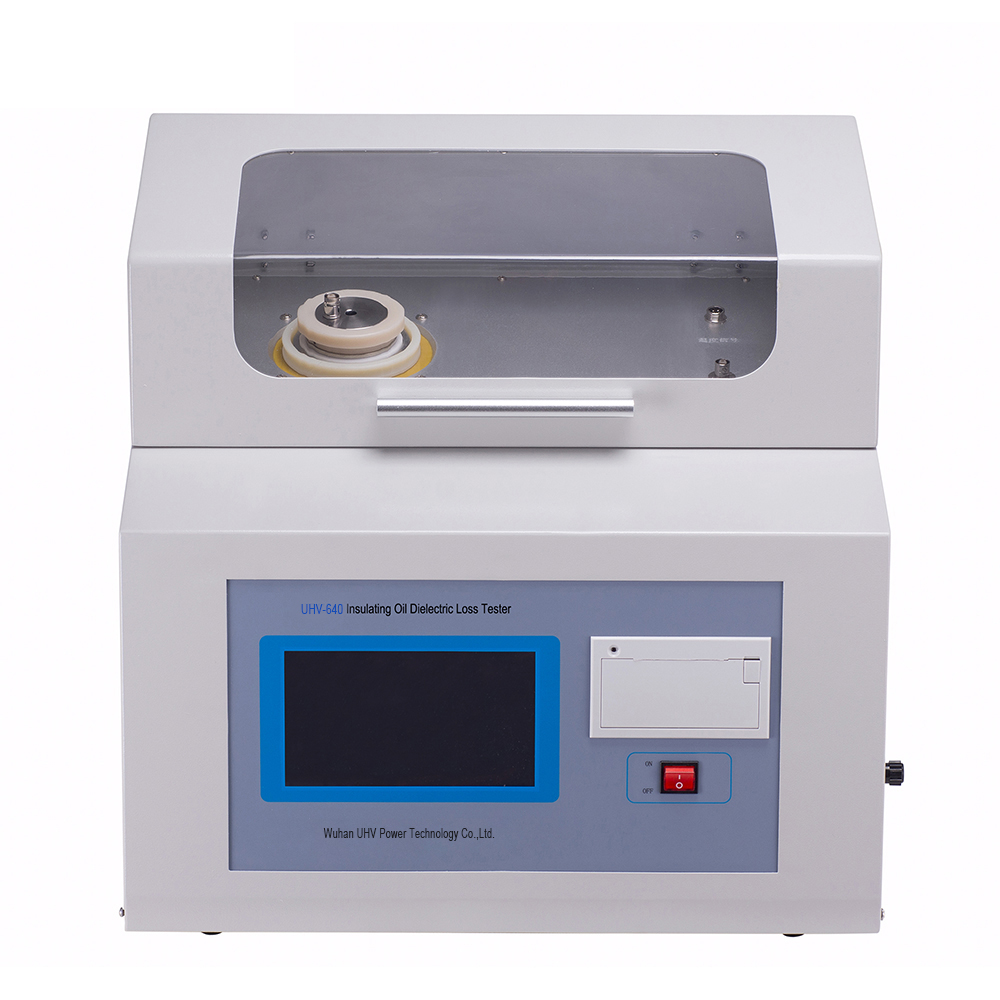

The insulation oil dielectric loss tester under UHV power can help many power workers conduct various power tests more conveniently.

Cleaning the oil cup is a very important preparation work when measuring the loss value of insulating oil with an insulation oil dielectric loss tester. Some unreliable measurement results are often caused by incomplete cleaning of the oil cup. Therefore, strict cleaning methods must be followed to obtain reproducible and reliable measurement results.

When conducting the identification test of insulation oil loss coefficient, the oil cup should be thoroughly cleaned before each test. The cleaning steps are as follows:

a. Completely remove the oil cup and clean all components with chemically pure petroleum ether (distillation range 60-90 ℃) and benzene in sequence.

b. Rinse all components with acetone, then clean with neutral detergent.

C. Boil all components in 5% trisodium phosphate in distilled water for 5 minutes, then rinse several times with distilled water.

d. Boil all components in distilled water for at least 1 hour.

e. Dry all parts in an oven controlled at 105-110 ℃ for at least 1 hour.

F. When all components have cooled down to a point where they won't be hot to the touch, assemble the oil cup.

Note: In the general routine test of insulation oil loss coefficient, the cleaning method of the oil cup can be simplified by omitting items c and d of the above cleaning method, and rinsing all components with distilled water several times instead. Then proceed directly to option e.

In addition, when conducting routine tests on a batch of oil samples continuously, if the loss factor of the previous oil sample is less than the specified value, it is not necessary to clean the oil cup during the next oil sample production. However, a second oil sample must be used and the oil cup must be rinsed three times or more.