The insulation oil dielectric strength tester under UHV power can help many power workers conduct various power tests more conveniently.

In order to understand the withstand voltage testing work of the insulation oil dielectric withstand voltage tester, you need to know where the high-voltage power supply is connected. One side of the voltage tester is usually connected to the power safety ground (ground wire). The other side of the power supply is connected to a high-voltage conductor. This power connection can connect a given conductor in two places: high voltage or ground.

When you perform two or more withstand voltage tests, you connect one contact to high voltage and all other contacts to ground. Conducting contact testing in this way ensures that it is isolated from all other contacts. What happens when you test something more complex than your first encounter? The series of contacts that connect wires, resistors, capacitors, diodes, and other components is called a "mesh" connection (or "mesh"). All high-voltage connections in the voltage withstand test network and all other contacts in the connected equipment are grounded. For example, if you have a wire connecting two pins, high voltage will be applied to both pins simultaneously, and the voltage on the wire will increase. All other wires and sockets are fixed. If you have two pins connected to a resistor, the voltage drop on both pins of the resistor always rises to zero. The entire resistor increases the voltage. In summary, all pins of a component always see the same voltage. Applying voltage in this way ensures that the remaining parts of the device are separated from the main body of the component.

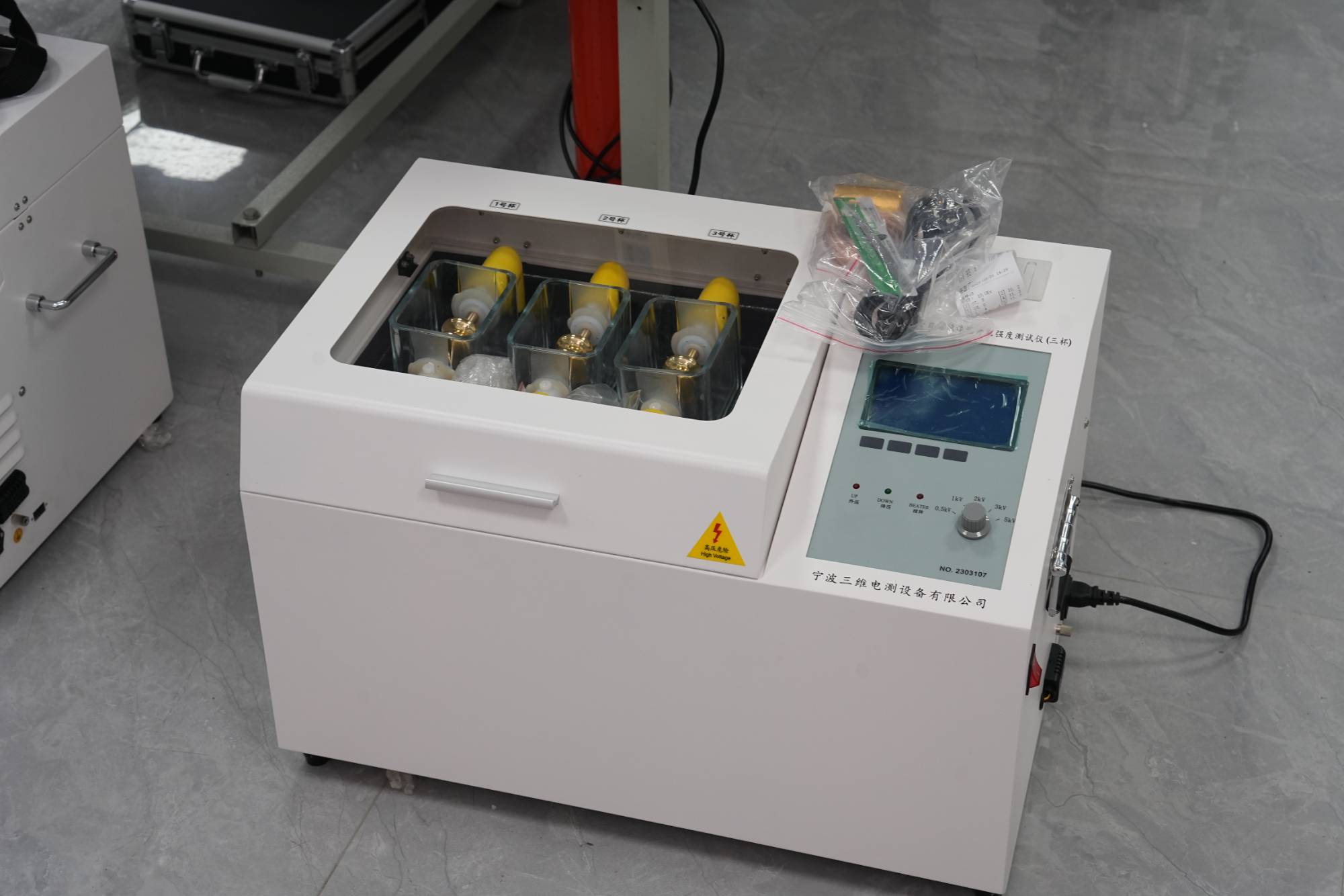

The insulation oil dielectric withstand voltage testing machine adopts a microprocessor, and three cups can automatically complete operations such as boosting, holding, mixing, electrostatic discharge, calculation, printing, etc. It can perform oil cycle withstand voltage testing within the range of 0-80kV (0-100kV). Color touch LCD screen, easy to operate through touch LCD screen. The operator only needs to make simple settings, and the instrument will automatically complete pressure tests for 1-3 oil samples according to the settings. For each oil sample, the breakdown voltage value and cycle count will be automatically stored. After testing, the thermal printer can print the breakdown voltage value and the average value each time, keep it powered off, store 100 experimental results, and display the current ambient temperature and humidity. Using a microcontroller to control constant speed boosting, the voltage frequency is accurate to 50Hz, making the entire process easy to control. It also has overvoltage, overcurrent, limit protection, etc., ensuring the safety of operators. It has temperature measurement display function and system clock display.

Dielectric breakdown testing is used in the product design and certification stages. It helps to build high-voltage designs. It is also possible to verify that the high voltage remains unchanged based on random sampling.

Dielectric breakdown testing may be required for critical application components during the development process.

Other high-voltage testing resources:

The AC withstand voltage test guide uses voltage insulation defects to detect high-voltage arc distance.

Usually, insulation resistance testing is performed on each test cable. It is typically 300 to 500 VDC and has a resistance of 100 to 500 Mbps. This test is highly sensitive to contamination during the assembly process. Many testing standards require voltage withstand testing for each cable. The test is usually about 75% of the typical breakdown voltage. This is to create a safety net. Testing is very sensitive to arcing or corona, so insulation oil dielectric withstand voltage testers often discover issues such as terminal spacing, overmolding, and IDC cable tolerance errors, which can all cause arcing. This test will not significantly reduce the cable. Flux, oil, release agent, and skin oil can cause problems. Proficient in identifying the presence of moisture in insulation, this test will be conducted.