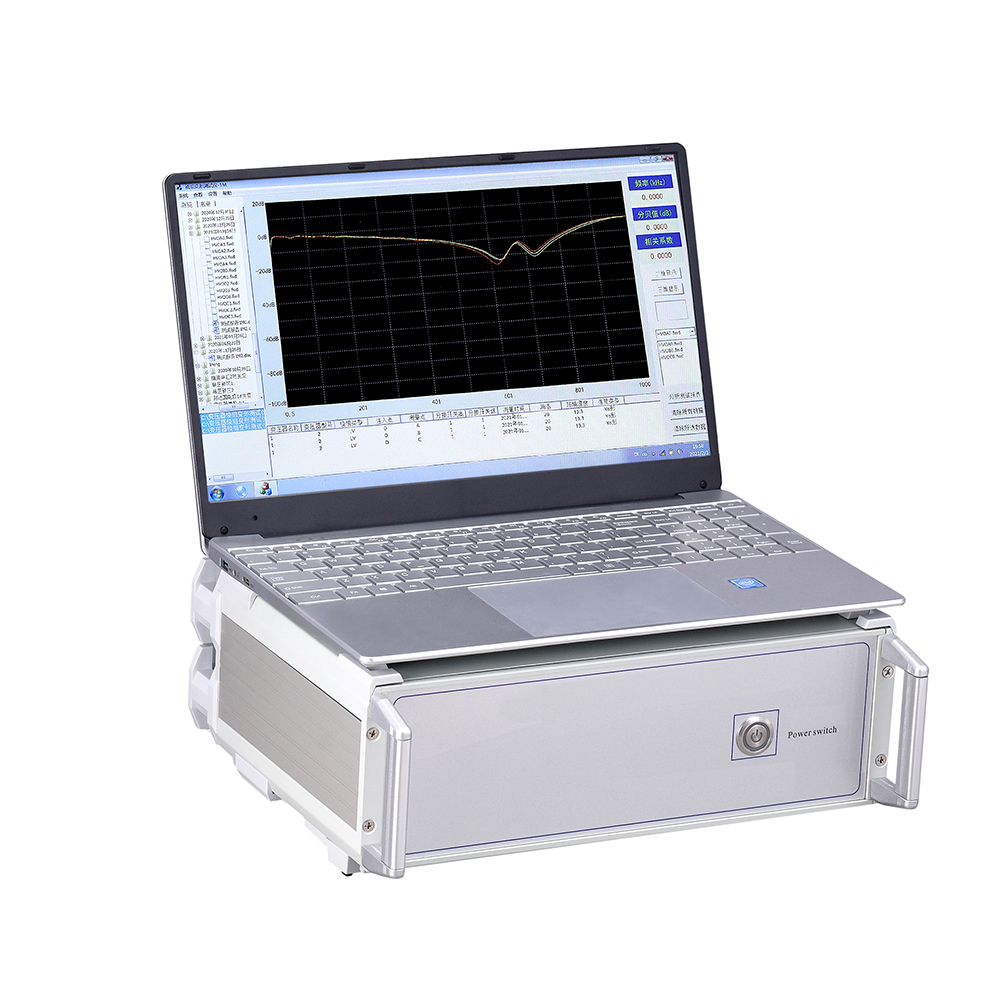

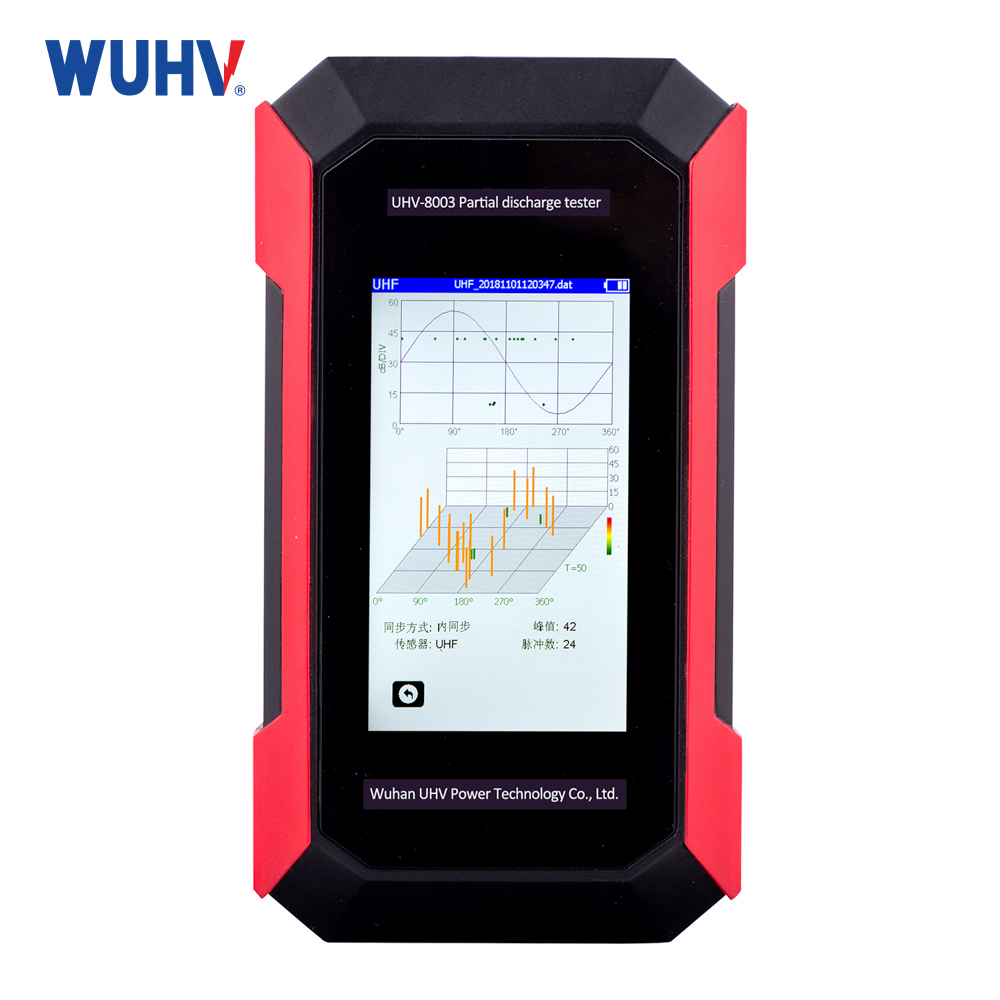

The UHV power professional production transformer winding deformation tester can help many power workers conduct various power tests more conveniently.

Precautions for determining transformer winding deformation:

a) The necessary conditions for transformer winding deformation are outlet short circuit, near-field short circuit, multiple overcurrent actions, and collisions during transportation;

b) The frequency response curves of the low-frequency part (tens of kHz) can generally overlap well, otherwise it is suspected that the test wiring has poor contact;

c) Generally speaking, transformers of 35kV and below (including those undergoing factory renovation) may have poor frequency response characteristics, and original data comparison should be retained during handover;

d) The measured frequency response curve is generally between+20 and -80 dB. If exceeded, check whether the test circuit has poor contact or disconnection;

e) When the angle winding is tested separately, the three-phase frequency response characteristics may not be consistent;

f) Balancing windings may result in inconsistent three-phase frequency response characteristics;

g) Severe distortion of windings can affect the frequency response characteristics of adjacent windings;

h) Due to poor craftsmanship, the frequency response characteristics of transformer windings may not be consistent in some small factories and on-site maintenance transformers;

i) There is evidence to suggest that temperature has an impact on frequency response characteristics;

j) When the entangled winding has transposed conductors, the frequency response characteristics of the transformer winding may not be consistent;