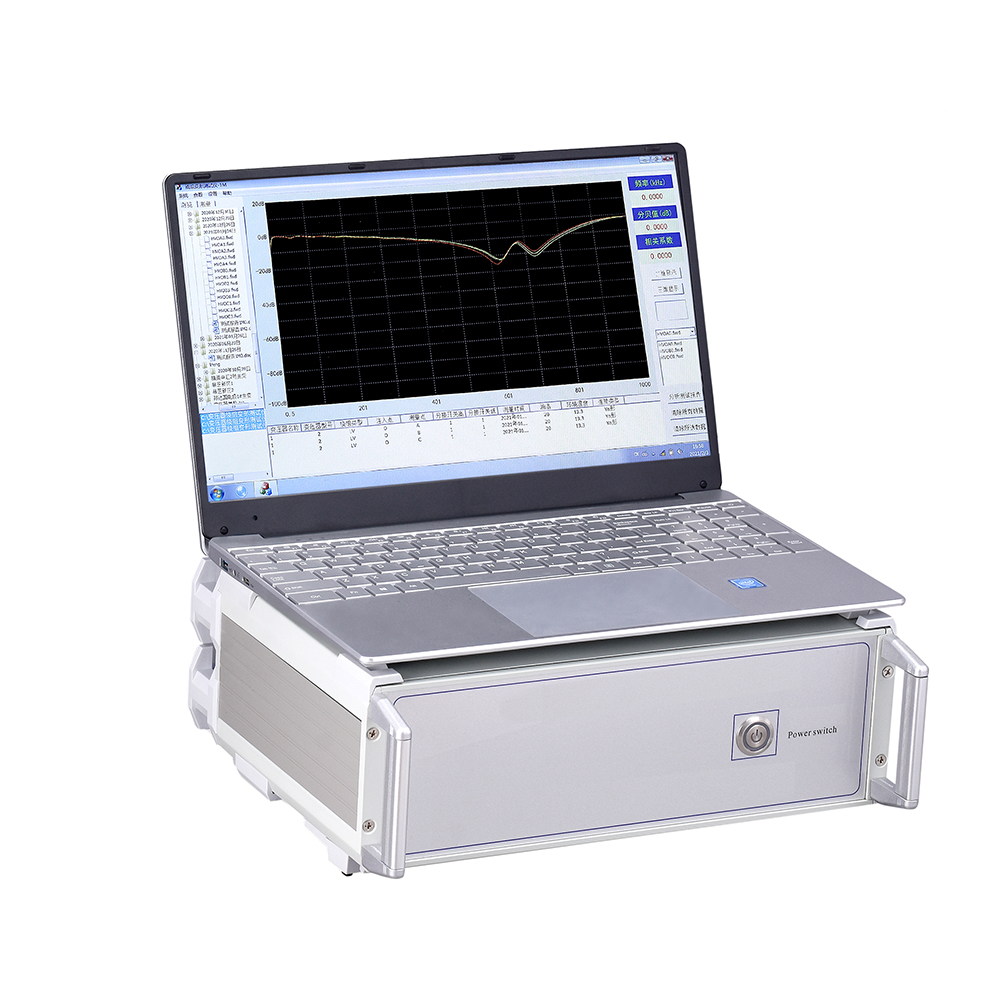

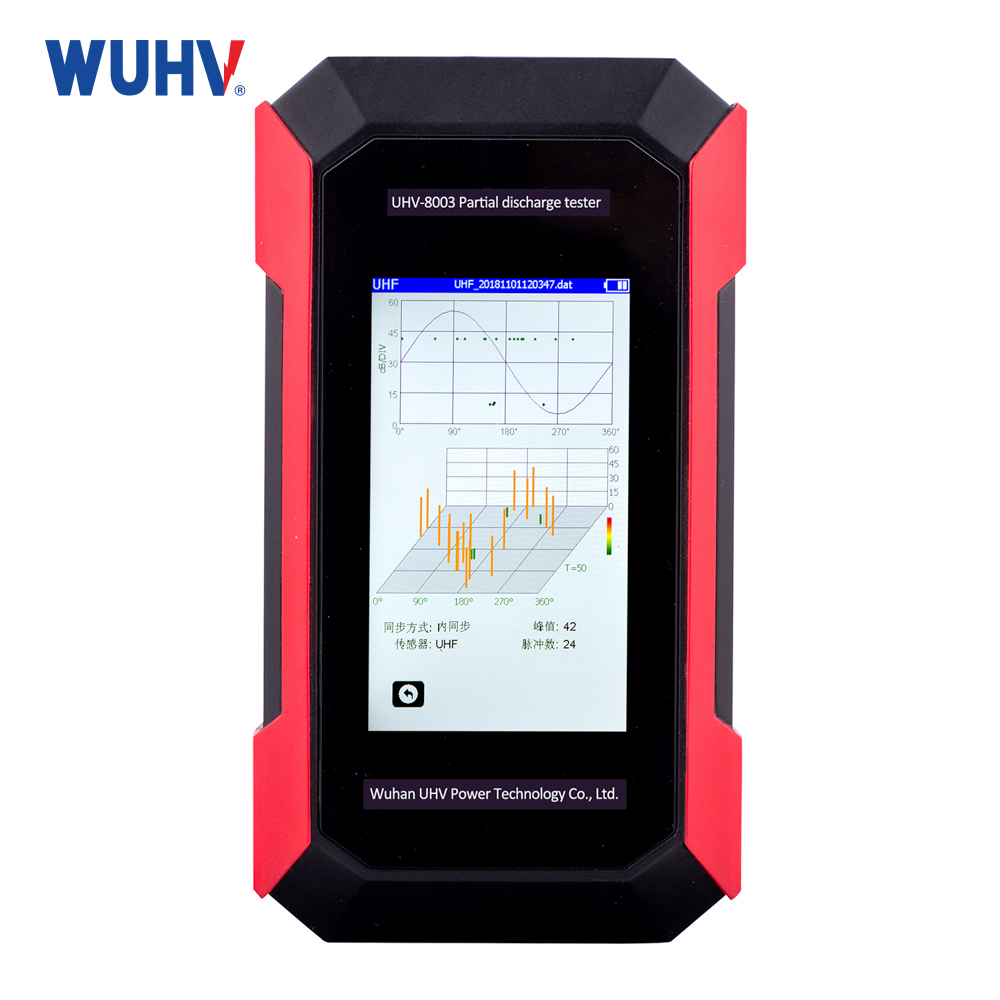

The UHV power professional production transformer winding deformation tester can help many power workers conduct various power tests more conveniently.

1) The tested transformer must be completely isolated from the power grid, and all coil leads must be disconnected from the busbar and kept away from the transformer terminals. Transformer winding deformation detection must be carried out before the DC test project or after the transformer winding is completely discharged, otherwise it will affect the repeatability of the test data and even cause damage to the test instrument.

2) The amplitude frequency response characteristics of transformer windings are related to the position of the tap changer. The test should be conducted at the highest tap position, or the tap changer should be in the same position for each test.

3) All wiring should be firm and reliable.

4) The BNC end of the test cable is connected to the BNC end of the same color code on the host, and the red and yellow test clips are reliably connected to the input and measurement ends of the tested coil, respectively.

5) The ground wire of the test clamp should be reliably connected to the grounding terminal on the transformer casing (such as the iron core grounding terminal), and the ground wire should be as short as possible and not tangled.

6) The safety grounding of the instrument must be reliably connected to the grounding busbar of the transformer base through the provided grounding cable.